Fabrication + Design

Form, Function and Fabrication

From precision cutting tools to advanced 3D printers, my experience bridges digital fabrication and tactile experimentation. I've worked across industrial labs—not only using tools, but maintaining them, troubleshooting failures, and collaborating closely with vendors and technicians to ensure consistent output. I’ve written detailed SOPs for engineers, led maintenance routines, and optimized workflows with an eye toward safety, sustainability, and fine detail. Below is a selection of tools I’ve used extensively and how they’ve shaped both my process and my approach to cross-functional collaboration.

Additive Manufacturing (3D Printing)

FDM (Fused Deposition Modeling)

Bambu Lab

Markforged FX20 + Desktop Series

Prusa MK3S (Personal home printer)

Used for functional prototypes and strong, repeatable prints. Comfortable with print prep, material selection, nozzle repair, and print troubleshooting.

SLA (Stereolithography)

Formlabs

Experience with resin prep, IPA wash, UV curing, and safe handling of biocompatible medical resins.

SLS (Selective Laser Sintering)

Formlabs Fuse 1

HP systems

Skilled in powder refresh strategies, print packing, and safe removal/post-processing of parts.

PolyJet

Stratasys J850 & J55

Used for multi-material prints with realistic color and flexibility. Maintained print quality through bed leveling, diagnostics, and printhead replacement. Particularly effective in medical modeling contexts.

Post-Processing + Finishing

Surface Smoothing & Sealing

DyeMansion Powershot, Powershot Dual Performance, and Powerfuse S

Familiar with gentle cycles for delicate geometries, hand-cleaning of internal cavities, and preparing prints for safe use or display.

Bead Blasting

Tabletop systems

Used for hands-on smoothing and cleaning of small SLS and SLA prints.

PolyJet

Stratasys Power Washer Jet

Used for processing multi-material parts.

cutting, routing, and fabrication

Digital Cutting + Routing

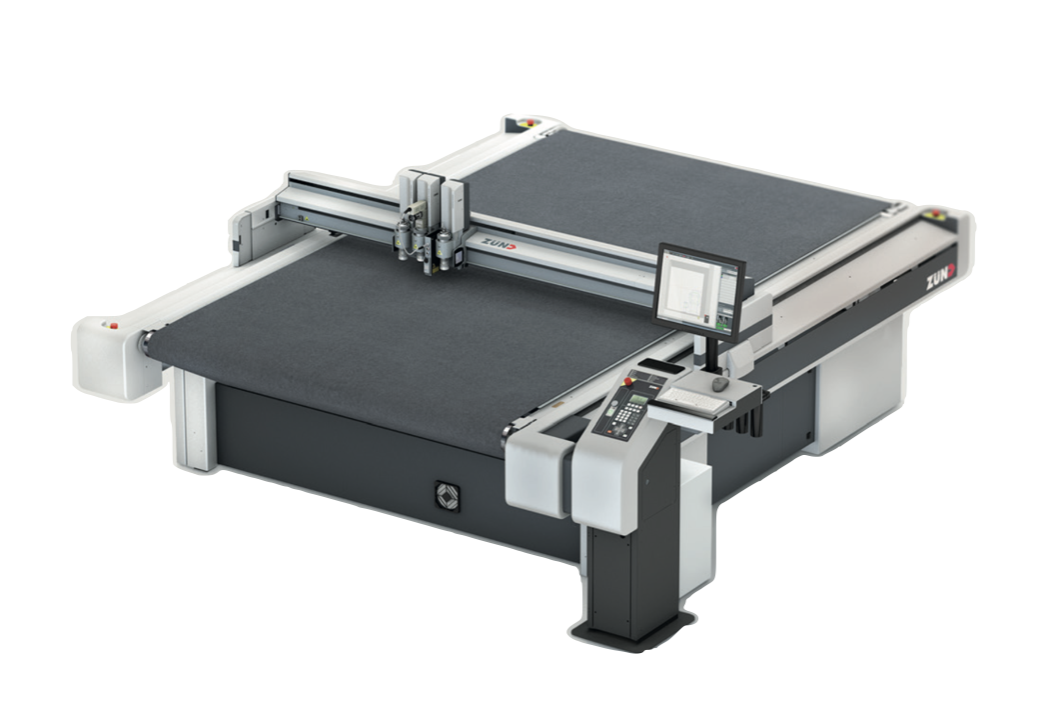

Zünd Knife & Router System

Kiss-cutting, depth calibration, material hold-down tuning, tool changeouts, and router path optimization.

Molding & Material Forming

Silicone Molding

Experience pouring, curing, and releasing silicone from 3D printed molds—aware of mold degradation under heat and print-cycle limits.

Pressure Plate Thermoforming

California-based pressure plate system

Used for both silicone curing and fabric thermoforming (e.g., pressing fabric to contoured surfaces). Managed material transitions and thermal timing to preserve form integrity.